Compliance with Industry Standards

Markings on press fittings ensure adherence to international codes like ISO 15874 and ASTM F877. These labels verify material grade, pressure ratings, and certification. For example, a fitting marked “ASTM F877-150” confirms it meets 150 psi standards for hot water systems.

Simplified Installation Verification

Markings help installers confirm correct orientation and compatibility. A 2023 study found unmarked press fittings caused 18% of errors in California hospital projects, including reversed flow direction in heating loops. Clear labels reduce such risks.

Traceability for Quality Control

Batch numbers or manufacturer codes enable defect tracking. When a German automotive plant recalled 500 press fittings in 2022, laser-etched codes identified faulty production lines within hours. This system minimized downtime in coolant systems.

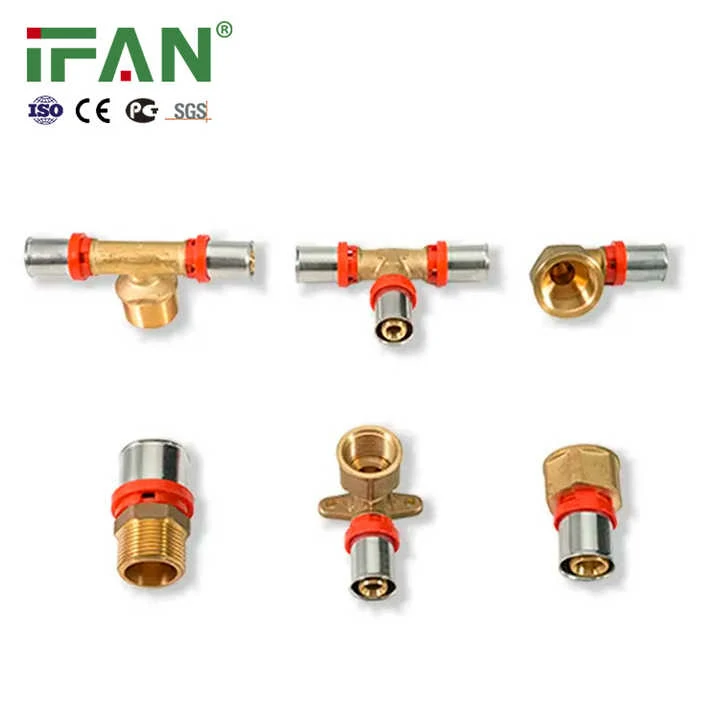

Preventing Material Confusion

Stainless steel and copper press fittings require distinct markings due to differing thermal properties. In a Singapore industrial park, color-coded rings (blue for copper, silver for stainless steel) eliminated 95% of accidental mix-ups in hybrid piping systems.

Maintenance and Repair Guidance

Expiry dates or inspection intervals on markings guide upkeep. A 2021 Dubai skyscraper project used UV-sensitive ink to show aging press fittings, triggering replacements when markings faded after 10 years of UV exposure.

Pressure and Temperature Limits

Stamped ratings (e.g., “MAX 200°F”) prevent system overloads. A Texas oil refinery avoided rupture risks by adhering to “3000 psi” markings on stainless steel press fittings during a 2020 pipeline upgrade.

Anti-Counterfeiting Measures

Holographic or micro-engraved markings deter imitation products. NIBCO’s 2023 anti-fake campaign reduced counterfeit brass press fitting in Southeast Asia by 70%, verified through smartphone-scannable QR codes.

Future-Proofing with Smart Markings

RFID tags or digital IDs are now embedded in premium press fitting. A pilot in Oslo’s smart city project (2024) uses NFC-tagged fittings to auto-update maintenance logs via building management systems.