Introduction

Understanding PPR Pipe Fittings: Types, Applications, and Benefits

Polypropylene Random Copolymer, widely referred to as PPR, has emerged as a prominent material for a variety of pipe fittings. This article will unravel the world of PPR pipe fittings, exploring their multifaceted types and delving into the industries where they find indispensable applications.IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com.

PPR Pipe Fittings Demystified

PPR pipe fittings are a testament to the remarkable properties of Polypropylene Random Copolymer. PPR, known for its exceptional resistance to temperature and pressure, is non-toxic and corrosion-resistant, making it an ideal material for crafting pipe fittings.

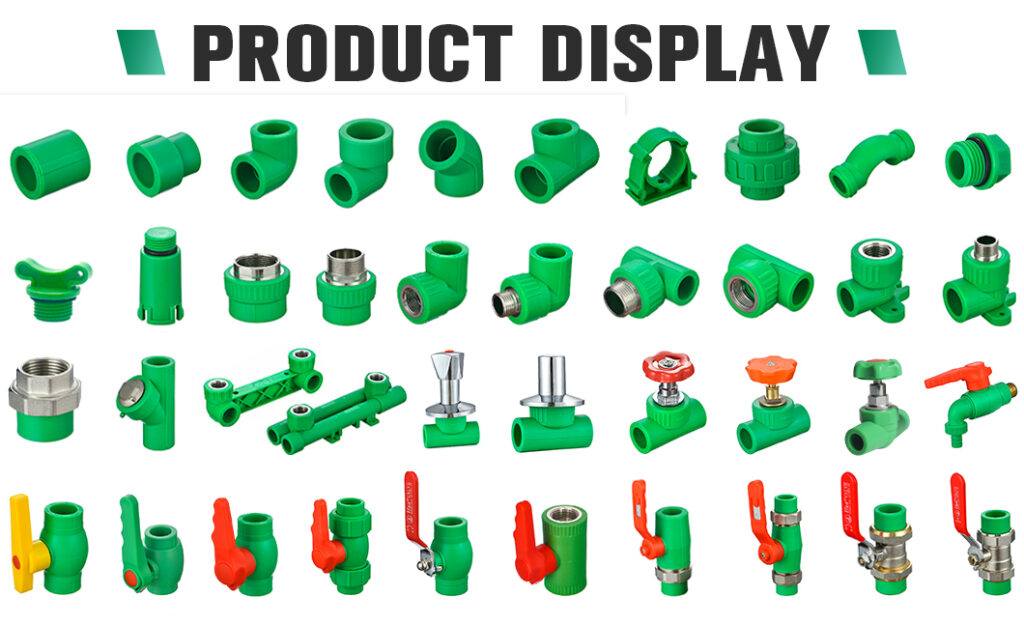

An Assortment of PPR Pipe Fittings

2.1. PPR Couplings: These fittings act as connectors, facilitating the union of two pipes or sections. Available in various sizes, PPR couplings are pivotal in both residential and industrial plumbing systems.

2.2. PPR Elbows: Elbows offer the flexibility to alter the direction of fluid flow. With options such as 45 and 90-degree angles, PPR elbows are indispensable in navigating complex plumbing layouts. Their application extends to plumbing and HVAC systems.

2.3. PPR Tees: Tees are responsible for creating branch connections in plumbing systems. They come in different configurations, including equal tees, reducing tees, and lateral tees, and are widely employed in residential and commercial plumbing.

2.4. PPR Reducers: Reducers enable the connection of pipes with varying diameters, ensuring a smooth flow transition. These fittings are pivotal for maintaining plumbing system efficiency.

2.5. PPR Caps: Caps provide a secure seal, closing off the end of a pipe and preventing leaks and contamination. They are employed across various industries, including water treatment and chemical processing.

2.6. PPR Flanges: Flanges serve the purpose of connecting pipes to valves, pumps, or other equipment, ensuring secure and leak-proof connections. Their significance is paramount in industrial applications.

Industries and Applications of PPR Pipe Fittings

3.1. Residential Plumbing: PPR pipe fittings are the preferred choice for residential plumbing systems. Their easy installation, corrosion resistance, and longevity make them highly favored among homeowners and construction professionals.

3.2. Commercial Plumbing: Commercial establishments, including hotels, hospitals, and office complexes, rely on PPR pipe fittings to ensure efficient water supply and distribution.

3.3. HVAC Systems: PPR fittings play a pivotal role in HVAC systems, ensuring the smooth transport of hot and cold fluids. Their resistance to temperature fluctuations makes them an ideal choice for this purpose.

3.4. Industrial Applications: In various industrial settings, including chemical processing and water treatment plants, PPR pipe fittings find application due to their chemical resistance and reliability.

3.5. Agriculture: Agricultural irrigation systems benefit from PPR fittings, ensuring the efficient distribution of water. PPR’s resistance to UV radiation and environmental factors makes it ideal for outdoor use in agriculture.

3.6. Infrastructure and Construction: Large-scale projects, such as water supply networks, wastewater systems, and stormwater management, rely on PPR pipe fittings for their durability and longevity.

3.7. Marine and Shipbuilding: PPR fittings are invaluable in marine and shipbuilding industries due to their resistance to saltwater and harsh environmental conditions.

The Advantages of PPR Pipe Fittings

4.1. Durability: PPR pipe fittings have a prolonged service life and resist corrosion and rust, guaranteeing reliable performance over time.

4.2. Easy Installation: Their lightweight and ease of handling simplify installation, reducing labor costs and installation time.

4.3. Chemical Resistance: PPR’s resistance to various chemicals makes it ideal for numerous industrial applications.

4.4. Non-toxic: PPR is non-toxic, ensuring that the transported fluids remain safe for consumption.

4.5. Thermal Insulation: PPR pipe fittings provide excellent thermal insulation, maintaining fluid temperature during transport.

Conclusion

PPR pipe fittings have revolutionized plumbing and fluid transport systems in diverse industries. Their range of types and applications demonstrates their adaptability and reliability. Whether in residential, commercial, industrial, or agricultural settings, PPR pipe fittings continue to be the preferred choice, thanks to their durability, ease of installation, and resistance to environmental factors. As technology and materials advance, PPR pipe fittings will continue to shape the future of plumbing and fluid transport systems across industries.