Introduction

Understanding PPR Pipe Fittings: Types, Applications, and Benefits

Polypropylene Random Copolymer (PPR) pipe fittings are a cornerstone of modern plumbing and fluid transport systems. Their diverse range of types and applications, coupled with numerous benefits, make them a preferred choice in various industries. In this article, we will explore the key types of PPR pipe fittings, delve into their applications across different sectors, and discuss the numerous advantages that come with their usage.IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com.

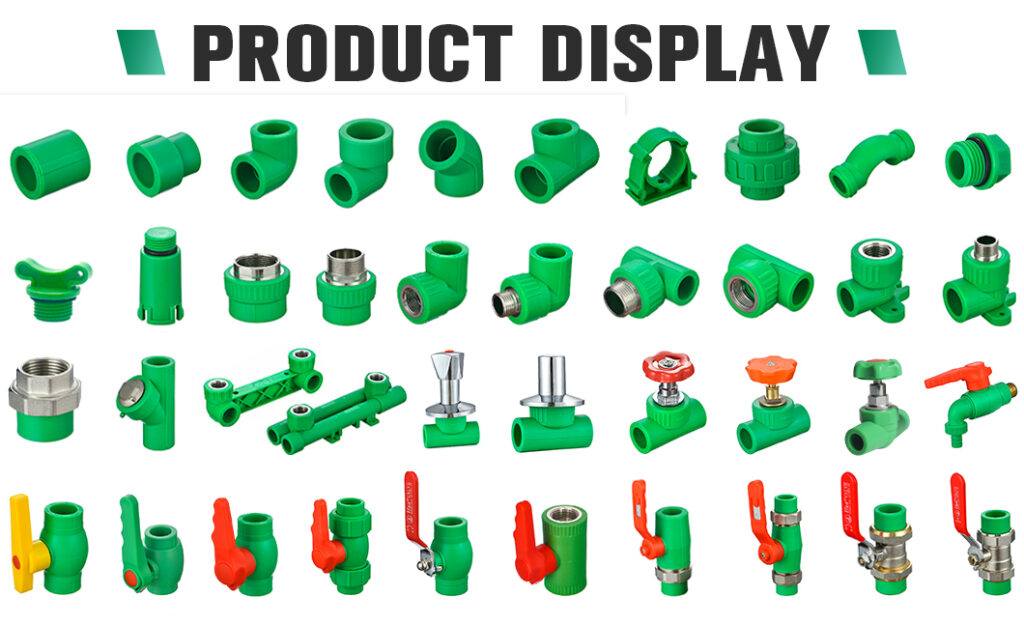

Types of PPR Pipe Fittings

1. PPR Elbow Fittings

PPR elbow fittings, available in 45 and 90-degree variants, are essential for redirecting the flow of fluids within a piping system. These fittings facilitate the efficient navigation of complex plumbing layouts.

2. PPR Coupler Fittings

Coupler fittings are used to join two PPR pipes of the same diameter. They come in a variety of sizes to accommodate different pipe dimensions, ensuring a secure and leak-free connection.

3. PPR Tee Fittings

Tee fittings are instrumental in dividing a pipe into two separate lines. They are invaluable for applications where water distribution or mixing is required.

4. PPR Reducer Fittings

Reducer fittings allow for the transition between larger and smaller pipe diameters, maintaining optimal flow rates within the plumbing system.

5. PPR Ball Valve Fittings

PPR ball valves offer a straightforward way to regulate fluid flow. They are widely employed in systems where precise control of on/off functions is necessary.

6. PPR End Cap Fittings

End cap fittings seal the end of a PPR pipe securely, preventing the ingress of contaminants. They are often used in the final stages of plumbing systems.

7. PPR Union Fittings

Union fittings comprise two female threaded ends and a union nut, enabling easy disassembly for systems that require periodic maintenance.

Applications in Various Industries

1. Residential Construction

PPR pipe fittings are a staple in residential plumbing systems. Their lightweight, corrosion-resistant, and leak-proof qualities ensure a safe and reliable water supply for households.

2. Commercial Buildings

In commercial construction, PPR pipe fittings play a vital role in maintaining efficient water supply, heating, and cooling systems. Their durability and resistance to scaling make them a dependable choice.

3. Industrial Facilities

Industries, such as manufacturing and processing plants, rely on robust plumbing systems. PPR pipe fittings excel in these demanding environments, handling high pressures and temperatures while transporting various liquids and chemicals.

4. Agriculture

Agriculture benefits from PPR pipe fittings in irrigation systems. Their corrosion resistance guarantees the longevity of irrigation networks, ensuring efficient water distribution to crops.

5. Chemical Industry

The chemical industry utilizes PPR pipe fittings for the safe transportation of chemicals. Their non-reactive nature ensures the integrity of chemical processes.

6. HVAC Systems

Heating, ventilation, and air conditioning systems in both residential and commercial buildings depend on PPR pipe fittings. Their corrosion resistance extends the lifespan of HVAC systems.

7. Swimming Pools and Aquatic Facilities

PPR pipe fittings are a common choice for swimming pools and aquatic facilities. Their resistance to pool chemicals, like chlorine, ensures water circulation and maintains water quality.

8. Food Processing Industry

In the food processing industry, where hygiene is paramount, PPR pipe fittings are used for the distribution of potable water and other liquids, ensuring the safety and quality of food production.

Benefits of PPR Pipe Fittings

Corrosion Resistance: PPR pipe fittings are immune to corrosion, making them ideal for applications involving various fluids and chemicals.

Leak-Proof: Their jointing system ensures a secure, leak-free connection, enhancing the reliability of plumbing systems.

Non-Toxic: PPR is non-toxic and safe for transporting potable water and fluids used in the food industry.

High Temperature Resistance: PPR pipe fittings can withstand high temperatures, making them suitable for hot water and industrial processes.

Easy Installation: Their lightweight nature and straightforward installation process reduce labor costs and installation time.

Longevity: PPR pipe fittings have a long service life, resulting in minimal maintenance and replacement costs.

Conclusion

Understanding the diverse types, applications, and benefits of PPR pipe fittings is essential for those involved in plumbing, construction, and various industries. Whether in residential, commercial, or industrial settings, PPR pipe fittings continue to play a vital role in ensuring the efficiency, safety, and longevity of fluid transport systems.