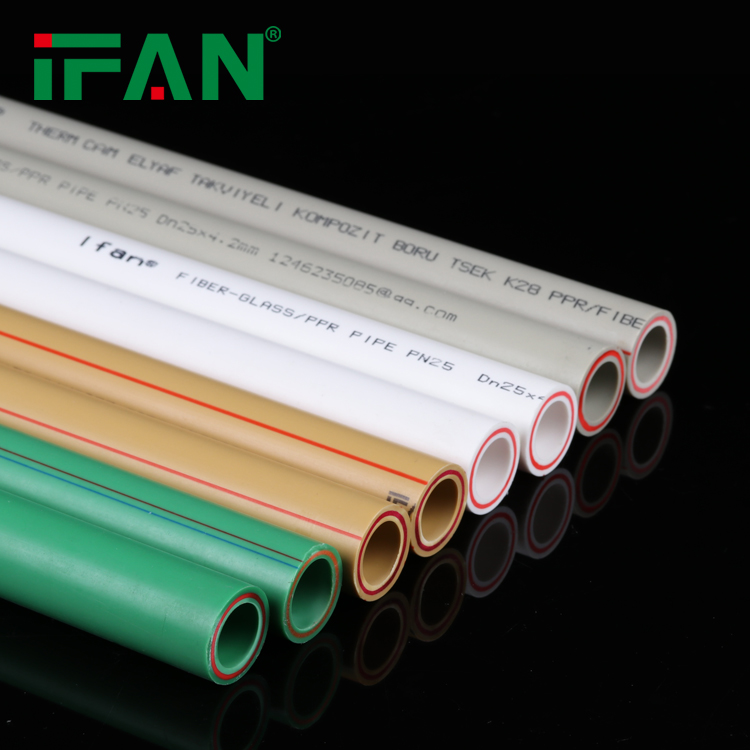

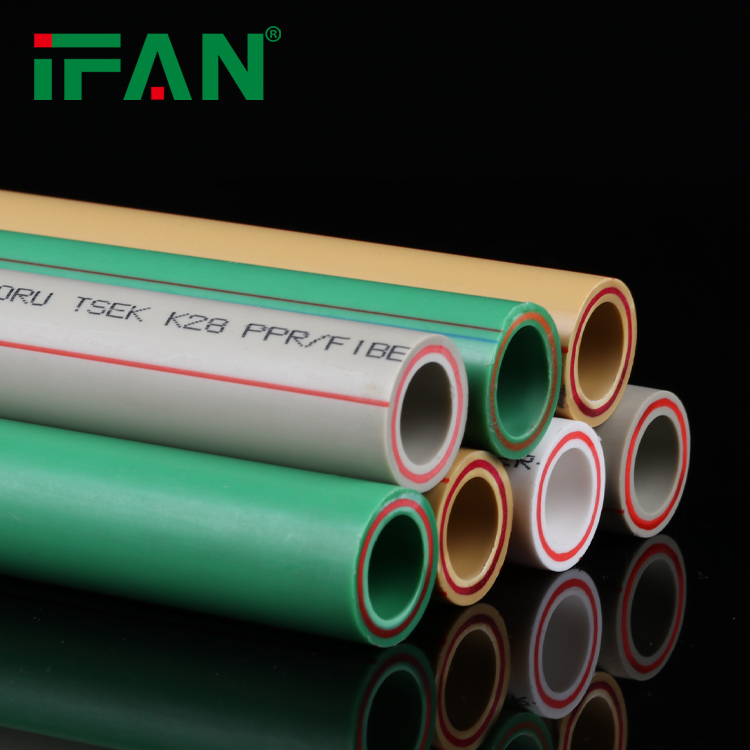

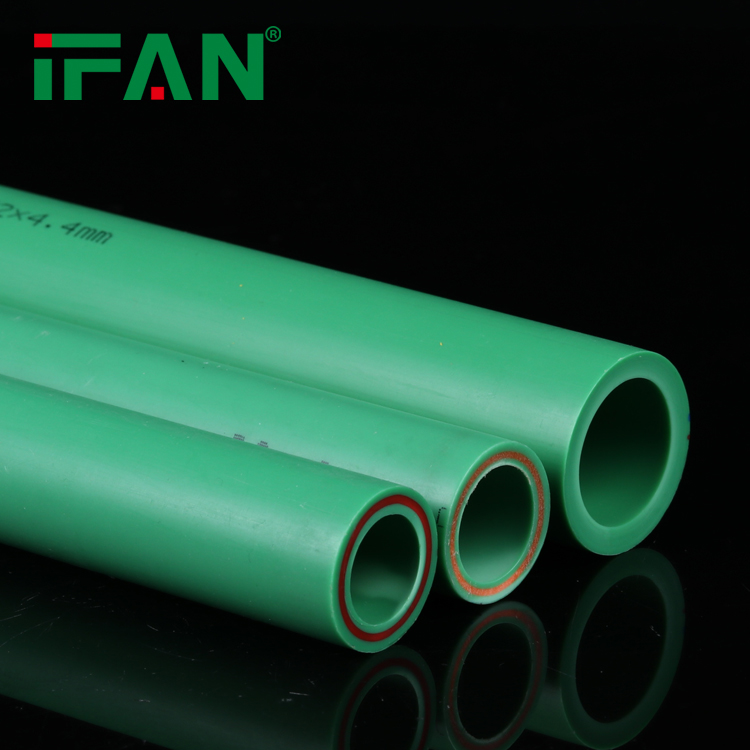

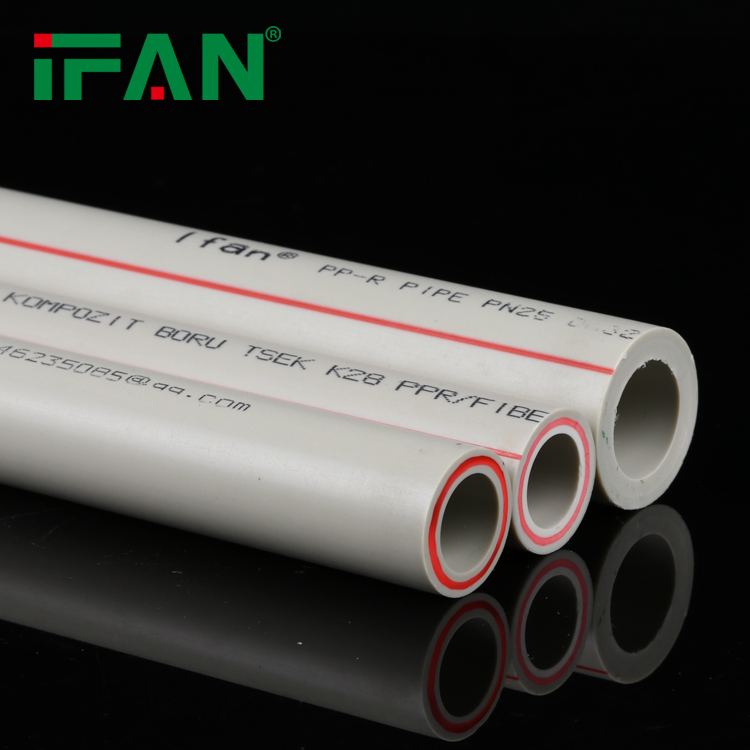

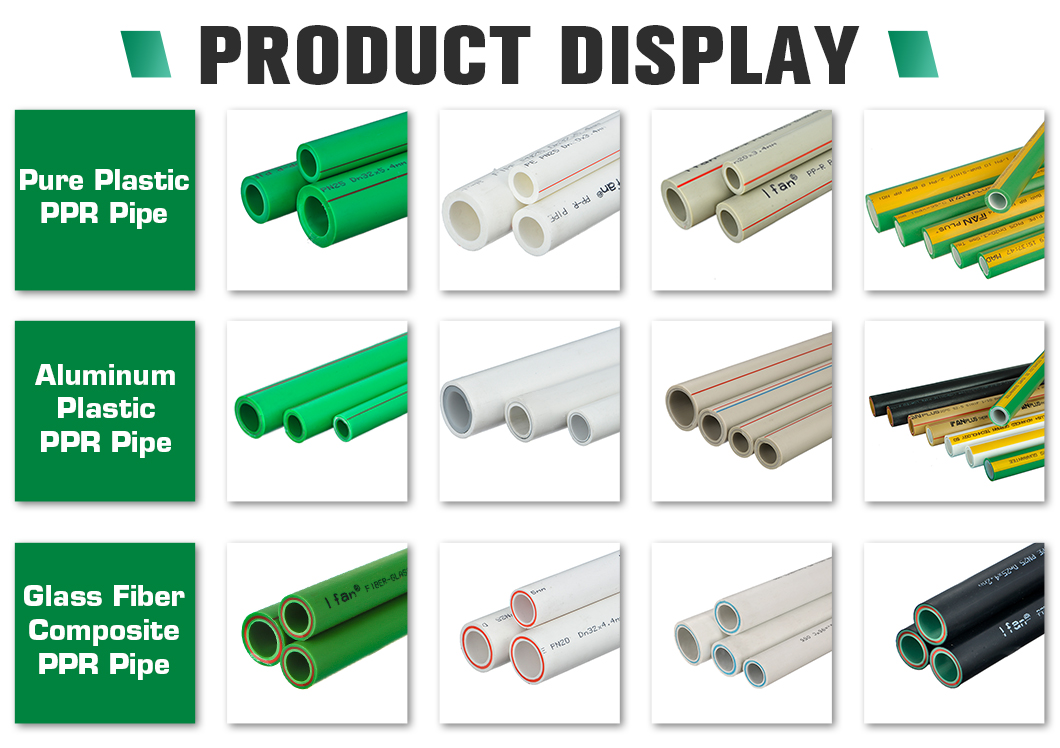

PPR Pipe

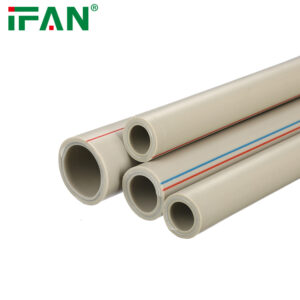

Product Name: PPR Pipe

Size: 20mm-110mm

Technics: Plastic injection

Work Temperature: -35℃ -110℃

Packing: IFAN Woven Bag

Sample: Free Sample

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

Introduce PPR pipe:

PPR pipe, also known as polypropylene random pipe, is a popular type of plastic piping commonly used in residential and commercial plumbing applications. PPR pipes have several advantages over traditional metal pipes, including their resistance to corrosion, low thermal conductivity, and easy installation. This article will provide detailed information about PPR pipes, including the characteristics of the raw material, the production process, the machine used, and tips to save it. This is our Facebook Website:www.facebook.com,IFAN factory has 30+ years manufacture experience supporting color /size customization support Free Samples.

Characteristics of the Raw Material:

PPR pipes are made of a thermoplastic polymer known as polypropylene random copolymer (PPR-C), which is a type of plastic that is known for its high strength, durability, and chemical resistance. PPR-C produces by combining propylene monomers with a small percentage of ethylene monomers, which gives the final product enhanced flexibility and impact resistance. PPR-C is also non-reactive, which means it is not affected by chemicals, acids, or alkaline materials.

The Production Process:

PPR pipes are using an extrusion process, which involves melting the raw material and forcing it through a die to create the desired shape. The extrusion process can break down into the following steps:

1. Mixing the raw material:

The PPR-C resin mix with additives such as stabilizers, antioxidants, and pigments to create a homogenous material.

2. Melting the raw material:

The mixed resin is then fed into an extruder, which heats the material until it melts into a viscous liquid.

3. Extruding the pipe:

The molten material is then forced through a die, which gives it its final shape and size. The extruded pipe is then cooled using a water bath, which helps it to solidify.

4. Cutting the pipe:

Once the pipe has extruded and cooled, cut to the desired length using a computer-controlled cutting machine.

The Machine Used:

The machine used for producing PPR pipes knows as a PPR pipe extrusion line. This machine consists of several components, including an extruder, a die head, a cooling water tank, a haul-off machine, and a cutting machine. The extruder is responsible for melting the raw material, while the die head shapes the molten material into a pipe. The cooling water tank cools the pipe and helps it to solidify, while the haul-off machine pulls the pipe through the line at a constant speed. Finally, the cutting machine cuts the pipe into the desired length.

How to Save PPR Pipes:

PPR pipes are known for their durability and long lifespan, but to ensure that they last as long as possible, it is essential to take good care of them. Here are some tips to help save your PPR pipes:

1. Regular cleaning:

PPR pipes should be cleaned regularly to prevent the buildup of sediment and other materials that could damage the pipe over time. Use a non-abrasive cleaning solution to clean the inside of the pipe, and rinse thoroughly with water before use.

2. Avoid exposure to direct sunlight:

PPR pipes should not be exposed to direct sunlight or high temperatures, as this can cause them to become brittle and crack over time.

3. Avoid harsh chemicals:

PPR pipes are resistant to most chemicals, but they can be damaged by harsh chemicals such as bleach or acetone, so it is important to avoid using these substances around the pipes.

4. Proper installation:

PPR pipes should install properly, using the correct fittings and connectors, to ensure that they are secure and leak-proof. Improper installation can result in leaks and damage to the pipe. If you want to know more about our products, please feel free to contact IFAN, and we will provide you with the best choice!

Conclusion:

PPR pipes are an excellent choice for plumbing applications, thanks to their durability, chemical resistance, and ease of installation. By understanding the characteristics of the raw material, the production process, and how to properly care for them, PPR pipes can provide reliable service for many years. As with any plumbing system, proper installation and maintenance are essential for ensuring the longevity of the system. By following these tips, you can help ensure that your PPR pipes last as long as possible.

相关产品

- PPR Pipe

IFAN High-Quality PPR Pipes

- PPR Pipe

Gray PPR-AL-PPR Pipe

- PPR Pipe

Reliable PPR Tube

- PPR Pipe

PPR Aluminum Plastic Pipe

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US