PPR Composite Pipe

Name:IFAN PPR Valve

Service: OEM ODM

Brand:IFAN</strong></span>

“font-size: 14pt; color: #000000;”>Category : Click Download

Whatsapp : +86 19884503412

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

When it comes to installing piping systems for various applications, such as in plumbing, heating, and cooling, choosing the right materials is key for ensuring longevity, safety, and efficiency. One notable option in the market is the PPR composite pipe, which combines the benefits of two renowned materials, polypropylene and fiberglass, to provide a highly durable and reliable solution for various piping needs.

Click here to view more our information!

Production Materials

-100% Raw Korea Hyosung

-Aluminum

Production Process

The production process of PPR composite pipes involves combining these two materials via a coextrusion method, wherein the PP and fiberglass layers are bound together by a special glue layer. This process ensures the homogeneity and integrity of the pipe, as well as its resistance to external and internal pressures, high temperatures, and chemical attacks.

Attributes:

| Processing Service | Moulding, Cutting |

| Place of Origin | Zhejiang, China |

| Brand Name | IFAN |

| Specification | 20-160mm |

| Length | 4 meters |

| Application | Hot and Cold Water Supply |

Click here to get product catalog!

Advantages

PPR composite pipes offer many advantages compared to other piping materials, such as copper, PVC, and steel. Some of these advantages include:

– Durability: PPR composite pipes are resistant to impact, abrasion, and cracks, and have a lifespan of up to 50 years or more, depending on the usage and maintenance conditions.

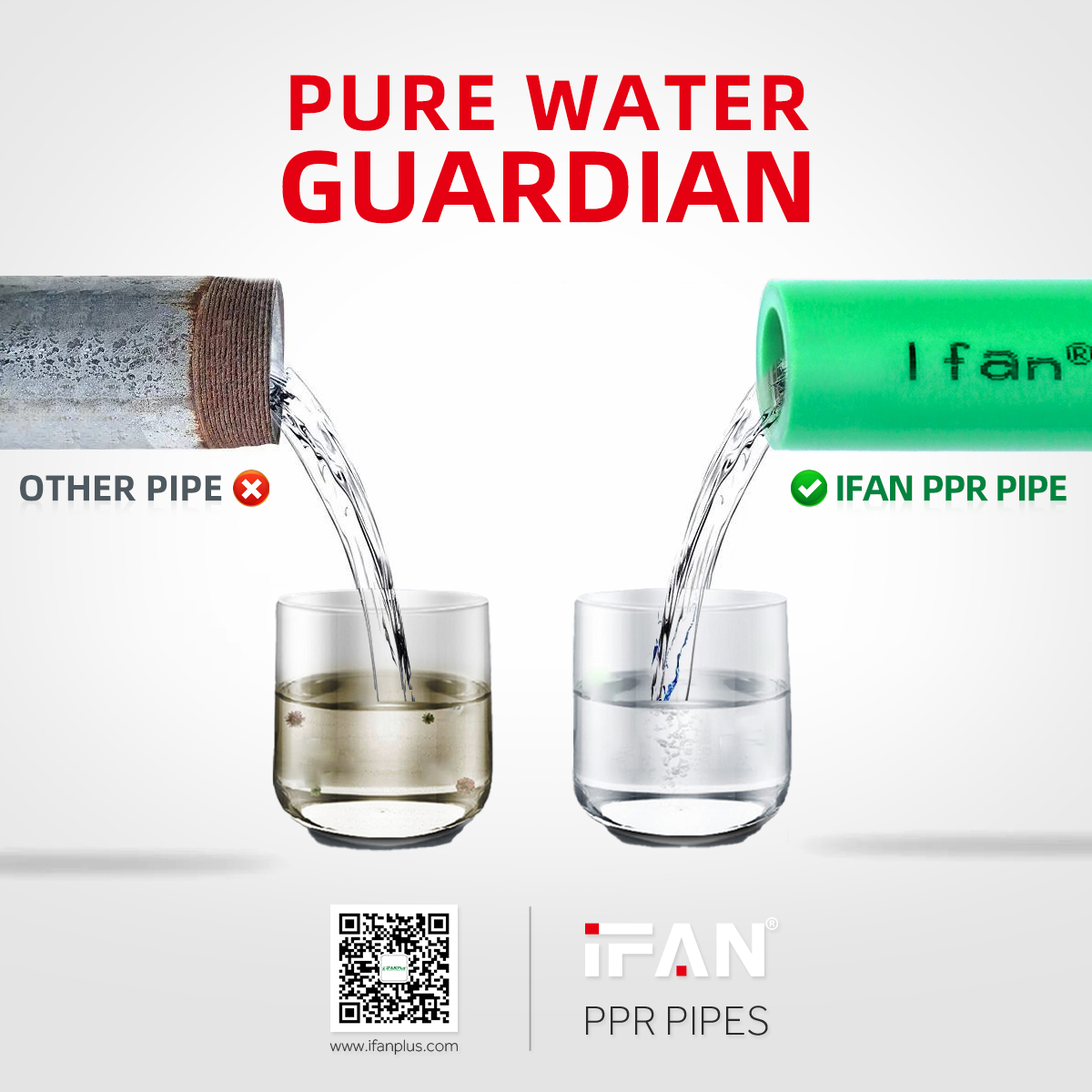

– Corrosion resistance: PPR composite pipes are highly resistant to corrosion, scaling, and chemical attacks, and do not suffer from rust, pitting, or leaching.

– Heat insulation: PPR composite pipes have low thermal conductivity, which means they can retain heat or cold better than other materials, and reduce heat loss or gain in the piping system, leading to energy savings and environmental benefits.

– Easy installation: PPR composite pipes are lightweight, flexible, and easy to handle and install, which reduces the labor and time needed for the installation, and minimizes the risks of leaks and accidents.

Specific Applications

PPR composite pipes are suitable for a wide range of applications, including:

– Hot and cold water supply for buildings, apartments, and hotels;

– Heating and cooling systems for residential, commercial, and industrial buildings;

– Chemical processing and transportation in factories and industries, such as petrochemicals, food processing, and pharmaceuticals;

– Gas transportation for residential and commercial use.

Conclusion

PPR composite pipes have proven to be a game-changing solution for piping needs, offering a reliable, durable, and efficient alternative to conventional materials. By blending the strengths of polypropylene and fiberglass, PPR composite pipes provide superior resistance to mechanical, thermal, and chemical stresses, while also being cost-effective, eco-friendly, and safe. Whether you need plumbing, heating, cooling, or chemical pipelines, PPR composite pipes can provide a long-lasting and hassle-free solution that will meet your requirements and exceed your expectations.

相关产品

- PPR Pipe

IFAN High-Quality PPR Pipes

- PPR Pipe

PPR Plumbing

- PPR Pipe

Gray PPR Pipe

- PPR Pipe

PPR Glass Fiber Pipe

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US