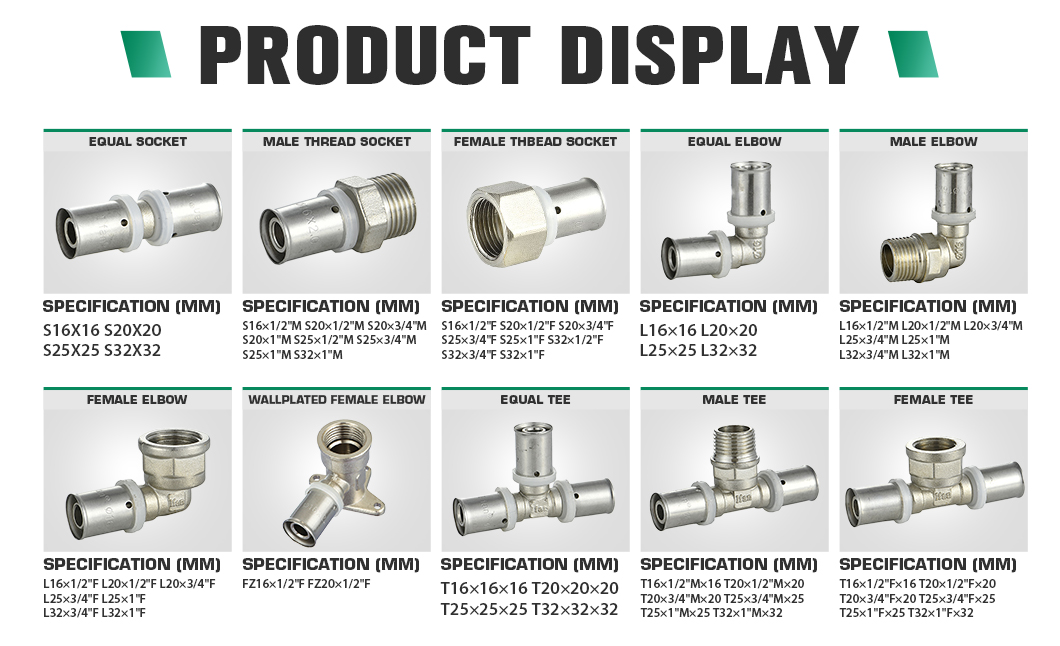

Pipe Press Fittings

Name: Pipe Press Fittings

Size: 20-32mm

Material: Brass

Application: Water system

Working pressure: ≤1.6MPa

Working temperature: -10℃≤ t≤120℃

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

Pipe press fittings are an essential component of plumbing and heating systems. They provide a simple, fast, and reliable way to make connections between PEX tubing and other components of the system. In this article, we will discuss the structure, material, manufacturing process, and flow of brass PEX press fittings.IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com

Structure

The structure of brass pipe press fittings is simple but effective. They consist of a brass body, a stainless-steel clamp ring, and an elastomeric sealing ring. The brass body is the main component of the fitting, providing the shape and structure required to hold the tubing securely. The stainless-steel clamp ring is used to compress the tubing onto the brass fitting, creating a leak-tight seal. The elastomeric sealing ring sits between the clamp ring and the PEX tubing, providing additional sealing support.

Material

The material used in brass PEX press fittings is vital to its functionality and durability. The brass body is typically made from a lead-free brass alloy, which is highly resistant to corrosion and chemical damage. The stainless-steel clamp ring is made from high-grade stainless steel, providing strength and corrosion resistance. The elastomeric sealing ring is typically made from EPDM rubber, which has excellent compression and sealing properties.

Manufacturing process

The manufacturing process of brass PEX press fittings is critical to ensure their reliability and durability. The process starts with the selection of high-quality raw materials, including lead-free brass, stainless steel, and EPDM rubber. The raw materials are carefully inspected, sorted, and stored to ensure their quality.

The next step is the production of the brass body, which is created by using a high-quality forging process. This process produces a highly durable and precise shape required for the fitting. The stainless-steel clamp ring is then cut and precision machined to create the required shape and size. The elastomeric sealing ring is usually molded to create the right shape and compression properties.

Once all three components are prepared, they are assembled into one unit using specialized machinery. The assembly process ensures that all components are correctly positioned and securely attached. The finished product is then tested for quality assurance, including leak testing and dimensional accuracy.

Flow

The flow of brass PEX press fittings is our last topic. These fittings are highly effective at ensuring the efficient flow of liquids through pipes and tubing. The design of the fitting provides smooth and consistent flow characteristics, minimizing pressure drops and maximizing flow rates. The use of high-quality materials and precision manufacturing techniques ensures the fittings’ durability, providing long-lasting performance and reliability.

In conclusion, brass PEX press fittings are an essential component of a plumbing and heating system. Their simple structure, high-quality material, and precise manufacturing process ensure that they are effective at making leak-tight connections. With smooth flow characteristics and durability, brass PEX press fittings are the perfect solution for any plumbing or heating system.

相关产品

- PEX Fitting

PEX Brass Pipe Fitting

- PEX Fitting

PEX Slide Sleeve Fitting

- PEX Fitting

PEX Compression Fitting Socket

- PEX Fitting

PEX Press Fittings

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US