Gray PPR Pipe

Product Name: Gray PPR Pipe

Size: 20mm-110mm

Technics: Plastic injection

Work Temperature: -35℃ -110℃

Packing: IFAN Woven Bag

Sample: Free Sample

Category : Click Download

Whatsapp : +86 19884503412

Wechat : 19884503412

Description

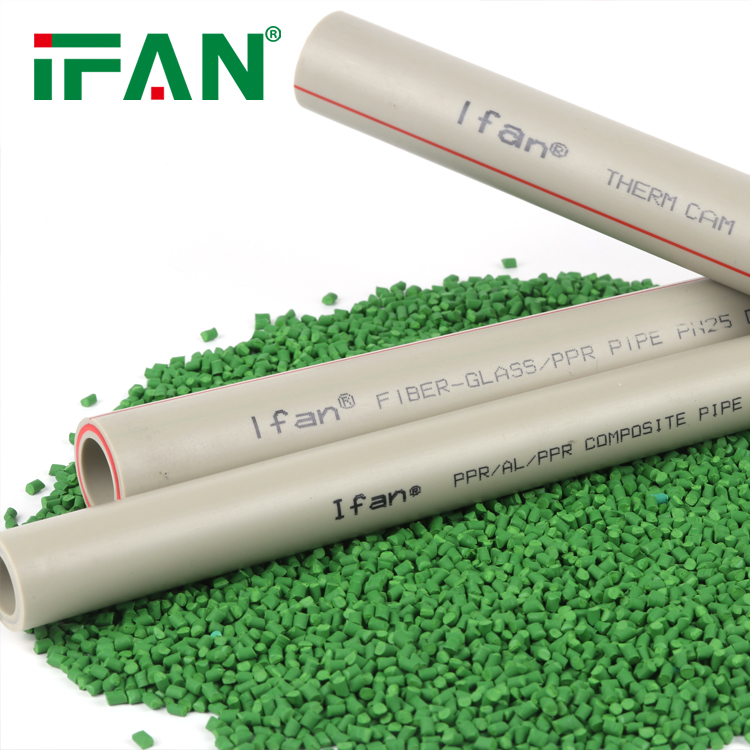

Gray PPR pipe is a versatile plastic pipe that is commonly used in the plumbing and heating industry. This type of pipe is made of polypropylene random copolymer (PP-R) and has a gray color. The use of PPR pipes has become increasingly popular due to its several benefits such as being resistant to corrosion, high temperatures, and chemicals. Moreover, PPR pipes are lightweight and easy to install, making them a preferred choice for many commercial and residential projects.

The production of gray PPR pipes involves several processes that require precision and attention to detail. In this article, we will discuss the technology used in the production process of gray PPR pipes. This is our Facebook Website:www.facebook.com,IFAN factory has 30+ years manufacture experience supporting color /size customization support Free Samples.

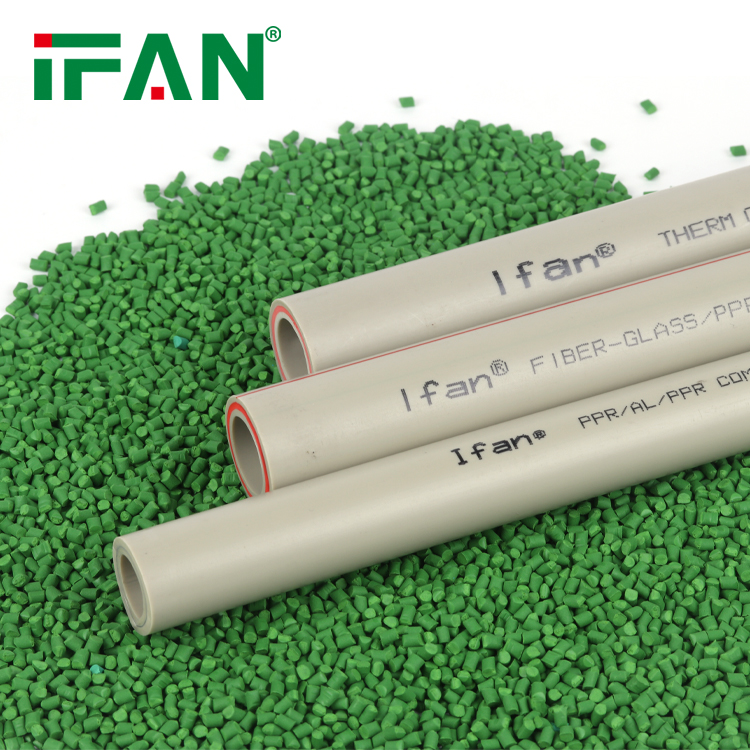

Raw Materials

The first step in the production process of gray PPR pipes is the selection of quality raw materials. PP-R is a thermoplastic polymer that is known for its high melting point, durability, and resistance to heat and chemicals. In the manufacture of gray PPR pipes, the polymer is mixed with a colorant to give the material a gray color.

Extrusion

The most crucial stage in the production process of gray PPR pipes is extrusion. Extrusion is the process of creating a continuous profile by melting a plastic material and forcing it through a die. The extrusion process for PPR pipes involves several steps.

The first step is the preparation of the raw materials. The PP-R granules are loaded into a hopper and mixed with the colorant to give the material a gray color. The mix is then melted at a high temperature of about 200-220°C in an extruder.

The next step is the extrusion of the gray PPR pipe. The melted material is forced through a die that gives it the desired shape and size. The pipe is then cooled using air or water to achieve the required hardness.

Cutting and Inspection

After the extrusion process, the gray PPR pipe is cut into the required lengths using a cutting machine. The cutting machine cuts the pipe into precise lengths and ensures that the ends are smooth and straight. The cutting process is an essential step as it determines the final length of the pipe, which should be accurate for easy installation.

The gray PPR pipe also goes through an inspection process to ensure that it meets the required standards. The pipes are inspected for any defects such as cracks, deformations, or discoloration. The inspection process is crucial for ensuring the safety and efficiency of the final product.

Packaging

The final stage in the production process of gray PPR pipes is the packaging. The pipes are packaged in bundlings that protect them from damage during transportation and handling. The packages are labeled with relevant information such as the pipe size, length, and manufacturer’s name. If you want to know more about our products, please feel free to contact IFAN, and we will provide you with the best choice!

Conclusion

Gray PPR pipes are a popular choice in the plumbing and heating industry due to their numerous advantages. The production process of gray PPR pipes involves several stages, from the selection of quality raw materials to the packaging of the finished product. Extrusion is the most crucial stage, and it involves the melting of the PP-R material and forcing it through a die to achieve the desired shape and size. Inspection and packaging are also essential stages in the production of gray PPR pipes to ensure that the final product meets the required standards. Overall, the production process of gray PPR pipes requires precision and attention to detail to achieve a high-quality product.

相关产品

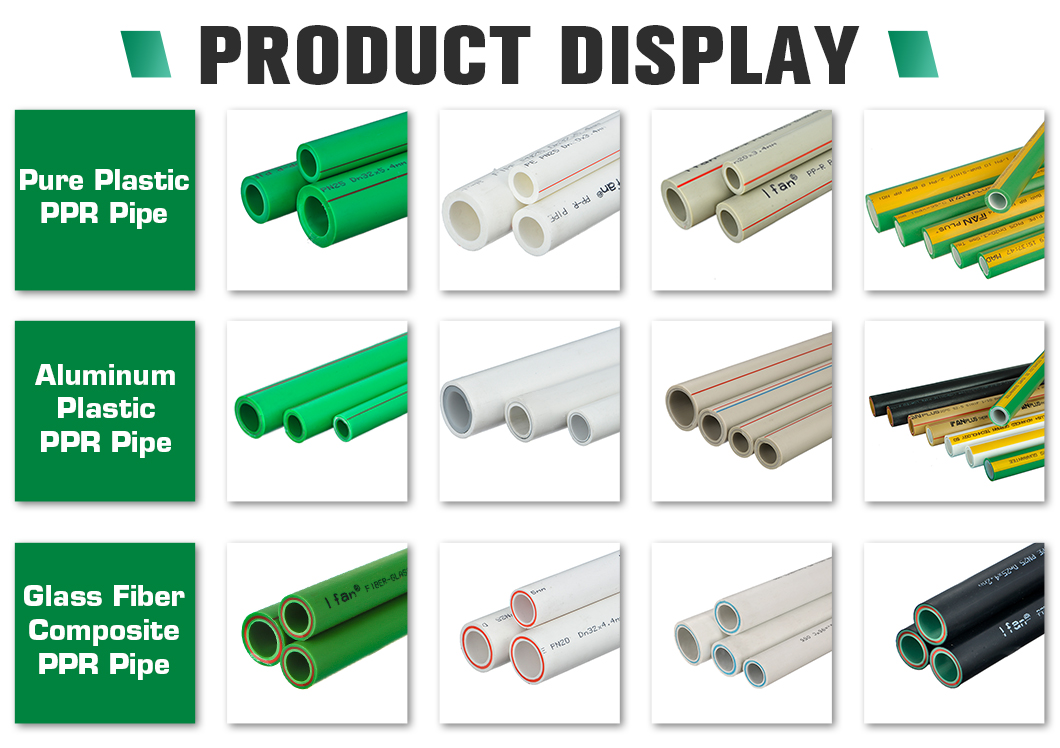

- PPR Pipe

PPR Composite Pipe

- PPR Pipe

IFAN All Colors PPR Pipe

- PPR Pipe

Gray PPR Plastic Pipe

- PPR Pipe

PPR Plumbing

HAVE ANY QUERIES? SEND TO CONTACTOANTSMACHINE.COM

ONTACT US