PPR Pipes: A Comprehensive Guide and Their Applications Across Industries.Polypropylene Random Copolymer (PPR) pipes have revolutionized plumbing systems across various industries due to their excellent attributes, including corrosion resistance, durability, and ease of installation. In this comprehensive guide, we will explore the basics of PPR pipes, their applications, and why they have become a popular choice across several sectors.IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our FacebookWebsite: www.facebook.com.

Introduction to PPR Pipes

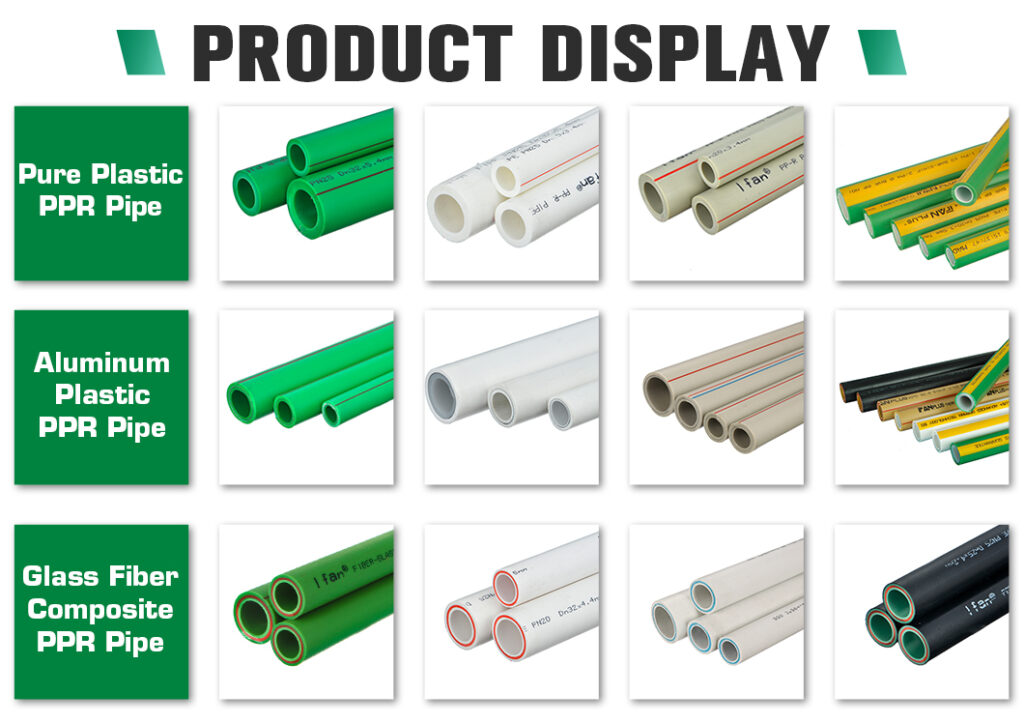

PPR pipes are a type of plastic piping system made from Polypropylene Random Copolymer, a thermoplastic material known for its exceptional performance in conveying liquids and gases. These pipes consist of three layers:

Outer Layer:

The protective outer layer shields the pipe from environmental factors, ensuring longevity.

Middle Layer:

This layer serves as a reinforcing structure, providing strength and stability to the pipe.

Inner Layer:

The innermost layer maintains the quality of the transported fluids, ensuring they remain uncontaminated.

Why Are PPR Pipes Popular?

PPR pipes have gained popularity across various industries due to the following advantages:

Corrosion Resistance: One of the most significant advantages of PPR pipes is their resistance to corrosion, ensuring the integrity of the pipe and the quality of the transported fluids.

High Strength: PPR pipes are incredibly durable and can withstand high pressure, making them suitable for a wide range of applications.

Thermal Stability: These pipes maintain their structural integrity even at high temperatures, making them ideal for hot water systems.

Low Maintenance: The long lifespan and durability of PPR pipes result in low maintenance costs, a significant benefit for both residential and industrial applications.

Hygienic: PPR pipes do not corrode or leach harmful substances into the water, ensuring the transported fluids remain uncontaminated.

Applications Across Industries

PPR pipes are versatile and find applications in a multitude of industries:

1. Residential Construction

PPR pipes are commonly used in residential construction for both cold and hot water supply systems. Their ease of installation, durability, and hygienic properties make them a preferred choice for homeowners.

2. Industrial Sector

The industrial sector utilizes PPR pipes for various purposes, including chemical transport, compressed air systems, and industrial water supply. Their corrosion resistance and strength are valuable assets in these applications.

3. Agriculture and Horticulture

PPR pipes are used in agricultural irrigation systems and greenhouse installations, ensuring a consistent and reliable water supply for crops and plants.

4. Swimming Pools and Spas

PPR pipes are integral components of swimming pool and spa systems. Their resistance to chlorine and high temperatures ensures the efficient circulation and maintenance of pool water.

5. Infrastructure Development

PPR pipes are used in infrastructure projects, such as municipal water supply systems, wastewater treatment plants, and drainage systems, where their durability and low maintenance requirements are crucial.

6. Commercial Buildings

In commercial structures like office complexes, malls, and hotels, PPR pipes are employed for their reliability in delivering water to various parts of the building and maintaining consistent hot water supply.

7. Renewable Energy Sector

PPR pipes play a vital role in solar water heating systems. Their ability to withstand high temperatures and thermal stability are well-suited for this application.

8. Food and Beverage Industry

PPR pipes are utilized in food and beverage processing facilities for their hygienic properties, ensuring the quality and safety of food and beverage products.

Installation and Maintenance

Proper installation and regular maintenance are crucial for the efficient operation of PPR piping systems. Considerations include selecting the right pipe diameter, maintaining appropriate temperature and pressure, and conducting routine inspections to identify and address any issues promptly.

Conclusion

PPR pipes have become an essential component in modern plumbing and fluid transport systems across various industries. Their remarkable attributes make them a preferred choice for applications where durability, corrosion resistance, and hygienic standards are of utmost importance. As technology and materials continue to evolve, PPR pipes are expected to play an even larger role in our ever-advancing industrial landscape.