kangyu When it comes to plumbing systems, selecting the right fittings is crucial for ensuring a leak-free and durable installation. PEX (cross-linked polyethylene) tubing has gained popularity in recent years due to its flexibility, affordability, and ease of installation. Among the essential fittings for PEX plumbing systems is the PEX compression male socket. In this article, we’ll delve into the installation essentials of this vital component.

IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples. This is our Facebook Website: www.facebook.com.

Understanding PEX Compression Male Socket

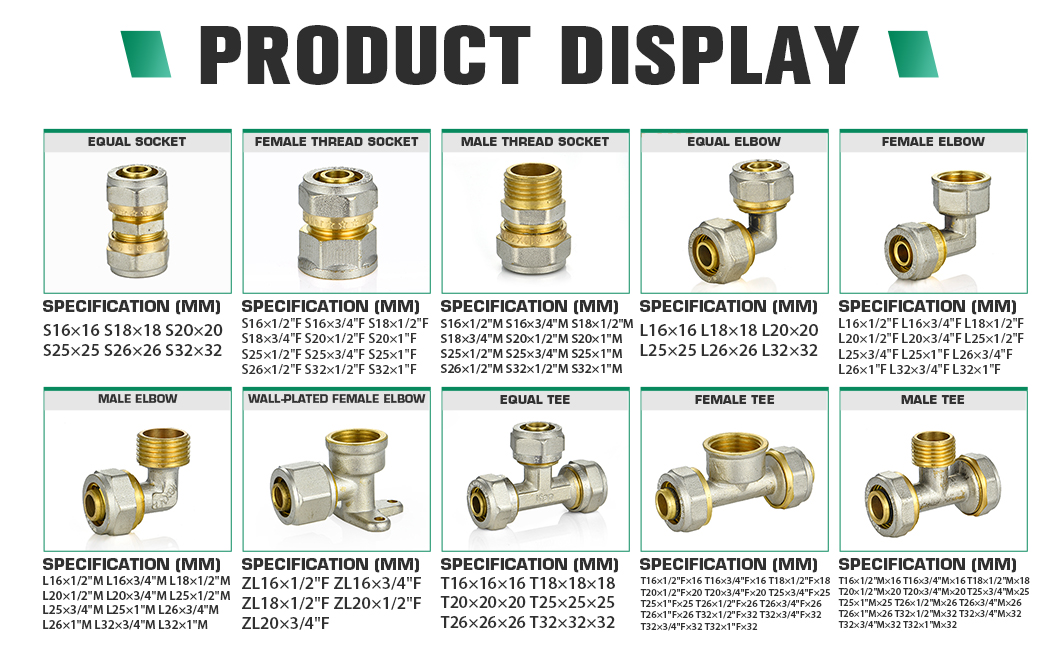

PEX compression male sockets are fittings designed to connect PEX tubing to various fixtures, valves, or other piping components. They feature a compression mechanism that tightly secures the PEX tubing, providing a reliable and watertight connection. These sockets are typically made from durable materials such as brass or stainless steel, ensuring longevity and resistance to corrosion.

Installation Process of PEX Compression Male Socket

Installing a PEX compression male socket requires attention to detail and adherence to proper procedures. Here’s a step-by-step guide:

Prepare the Tubing: Cut the PEX tubing cleanly using a PEX tubing cutter. Ensure the cut is straight and free from any burrs or debris that could compromise the seal.

Insertion: Slide the compression nut and compression ring (also known as the ferrule) onto the PEX tubing. Ensure they are positioned in the correct order and orientation for assembly.

Connection: Insert the PEX tubing into the male end of the compression socket until it reaches the bottom. Make sure the tubing is fully seated to ensure a proper seal.

Compression: Slide the compression nut over the compression ring and hand-tighten it onto the male end of the socket. Use a wrench to further tighten the nut, ensuring a secure connection. Be cautious not to over-tighten, as this can damage the fitting or tubing.

Check for Leaks: Once the connection is made, turn on the water supply and inspect the joint for any signs of leakage. If leaks are detected, tighten the compression nut slightly until the leaks cease.

Benefits of PEX Compression Male Socket

Versatility: PEX compression male sockets are compatible with various plumbing systems, including hot and cold water applications.

Reliability: The compression mechanism provides a secure and leak-free connection, reducing the risk of water damage and costly repairs.

Ease of Installation: Unlike soldering or crimping methods, PEX compression fittings can be installed without specialized tools or skills, making them ideal for DIY enthusiasts and professionals alike.

Durable Construction: Made from high-quality materials, PEX compression male sockets offer durability and resistance to corrosion, ensuring long-term performance.

In conclusion, PEX compression male sockets are essential components in PEX plumbing systems, offering reliable and watertight connections. By following proper installation procedures and understanding their benefits, homeowners and professionals can ensure efficient and durable plumbing installations for years to come.