chuangrong PEX (cross-linked polyethylene) plumbing systems have gained significant popularity in recent years due to their versatility, durability, and ease of installation. Among the essential components of a PEX system is the compression socket. In this article, we delve into the fundamentals of the Efficient PEX compression fitting socket, understanding its function, installation process, and advantages in modern plumbing applications.

IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com.

Understanding the Function of PEX Compression Fitting Socket

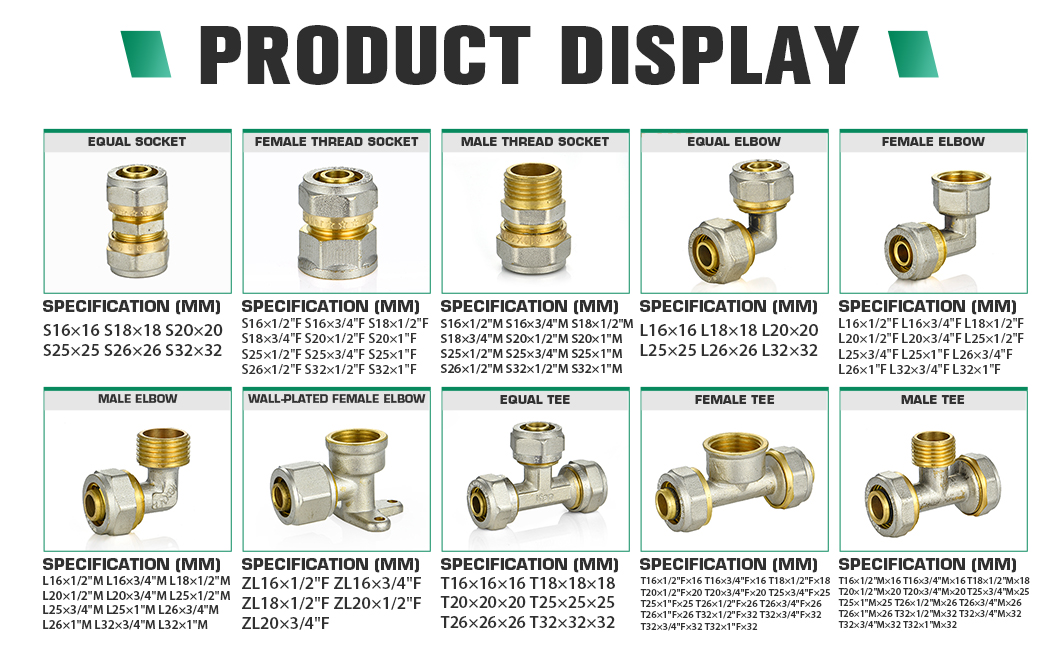

PEX compression sockets serve as crucial connectors in PEX plumbing systems, enabling secure and watertight joints between PEX pipes and fittings. These sockets feature a compression mechanism that ensures a tight seal, preventing leaks and ensuring the smooth flow of water or other fluids within the plumbing system.

Installation Process: Step-by-Step Guide

Installing a PEX compression socket requires precision and attention to detail to ensure optimal performance. Here’s a step-by-step guide to the installation process:

- Prepare the PEX Pipe: Cut the PEX pipe to the desired length using a PEX pipe cutter, ensuring a clean and straight cut.

- Deburr the Pipe: Use a deburring tool to remove any rough edges or burrs from the cut end of the PEX pipe, ensuring a smooth surface for proper fitting.

- Insert the Compression Ring: Slide a compression ring onto the end of the PEX pipe, ensuring it sits flush against the end of the pipe.

- Insert the Compression Sleeve: Insert a compression sleeve into the end of the PEX pipe, ensuring it is positioned inside the compression ring.

- Insert the Pipe into the Socket: Insert the prepared end of the PEX pipe into the PEX compression socket until it reaches the bottom, ensuring a snug fit.

- Tighten the Compression Nut: Use an adjustable wrench to tighten the compression nut onto the PEX compression socket, compressing the compression ring and sleeve to create a watertight seal.

- Check for Leaks: Once the connection is made, perform a thorough inspection to check for any leaks or signs of water seepage, addressing any issues promptly.

Advantages of PEX Compression Fitting Socket

- Versatility: PEX compression sockets are compatible with various PEX pipe sizes and types, offering flexibility in plumbing installations.

- Reliability: The compression mechanism ensures a secure and leak-free connection, providing peace of mind to homeowners and professionals alike.

- Ease of Installation: With a straightforward installation process and no need for specialized tools or equipment, PEX compression sockets streamline plumbing projects, saving time and effort.

- Durable Construction: Constructed from high-quality materials such as brass or stainless steel, PEX compression sockets exhibit excellent durability and resistance to corrosion, ensuring long-term performance.

Conclusion

In conclusion, the efficient PEX compression fitting socket plays a pivotal role in modern plumbing systems, offering reliability, versatility, and ease of installation. By understanding its function, installation process, and advantages, homeowners and professionals can harness the full potential of PEX compression sockets in their plumbing projects, ensuring efficient and durable plumbing solutions for years to come.