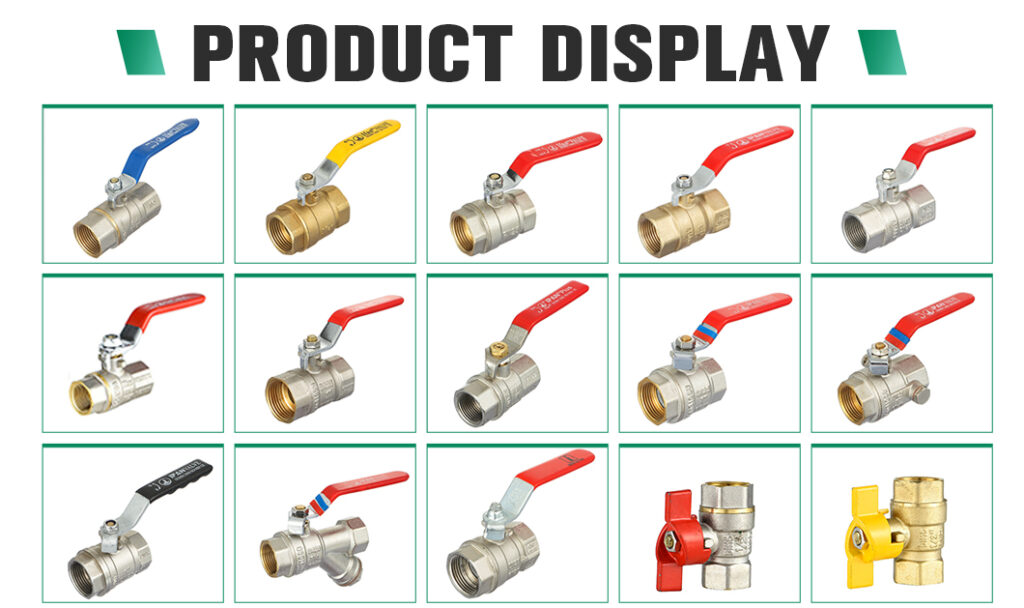

Ball valve is a common fluid pipeline control equipment, which is divided into two types: copper ball valve and non-copper ball valve. In actual use, it is necessary to select a suitable ball valve according to the specific use environment and fluid medium.today IFAN takes you to learn about ball valves.IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com

The difference between different material ball valves

The main difference between copper ball valves and non-copper ball valves is the difference in material. Copper ball valves are widely used in waterway systems, air-conditioning refrigeration, heating engineering and other fields. The material has good thermal conductivity, electrical conductivity and corrosion resistance, and its durability is relatively high. However, the price of copper ball valves is relatively high, and the weight is relatively large, so it is not suitable for large-diameter pipeline control.

The main materials used for non-copper ball valves include stainless steel, titanium alloy, copper-aluminum alloy, plastic, etc., which are suitable for various media and environments. Due to the good corrosion resistance, high temperature resistance and corrosion resistance of the material, stainless steel ball valves are widely used in chemical, petroleum, food, pharmaceutical and other industries. The plastic ball valve is suitable for some medium and low pressure and small diameter pipeline systems due to its light weight and affordable price.

How to choose a ball valve

For different industries and different pipeline systems, it is necessary to select a suitable ball valve according to the actual situation. The following factors need to be considered when selecting a ball valve:

- Operating environment: such as medium temperature, pressure, corrosion degree, ambient temperature, etc.

- Pipeline requirements: such as caliber, material, connection method, etc.

- Control requirements: such as control method, flow rate, etc.

- Safety requirements: such as whether there is a need for fire prevention, explosion protection and other functions.

At the same time, it is also necessary to refer to the technical parameters provided by the ball valve manufacturer, such as pressure rating, sealing level, flow characteristic curve, etc., in order to better choose a ball valve suitable for your own piping system.

The purchase of high-quality ball valves

Purchasing high-quality ball valves should follow the following principles:

- To choose a regular manufacturer.

- Pay attention to product quality and try to choose brand products.

- It depends on the product warranty period. Generally speaking, the longer the warranty period, the higher the degree of responsibility for product quality.

- Pay attention to after-sales service, including maintenance, replacement parts, etc.

- Pay attention to anti-fraud and avoid being misled by unscrupulous merchants.

When purchasing ball valves, appropriate products should be selected according to actual use needs, and the principle of quality priority must be followed, and the help of dealers must be actively sought. At the same time, pay attention to guard against fraudulent behavior of merchants to avoid buying bad brands, defective products and other products.