The main functions of valves are opening and closing, throttling, regulating flow, isolating equipment and piping systems, preventing backflow of media, regulating and discharging pressure, etc. Today IFAN introduces the key points of valve selection, follow us to learn more. This is our Facebook Website:www.facebook.com,IFAN factory has 30+ years manufacture experience supporting color /size customization support Free Samples.

Clarify the purpose of the valve in the equipment or device

Determine the working conditions of the valve: the nature of the applicable medium, working pressure, working temperature, manipulation control methods, etc.

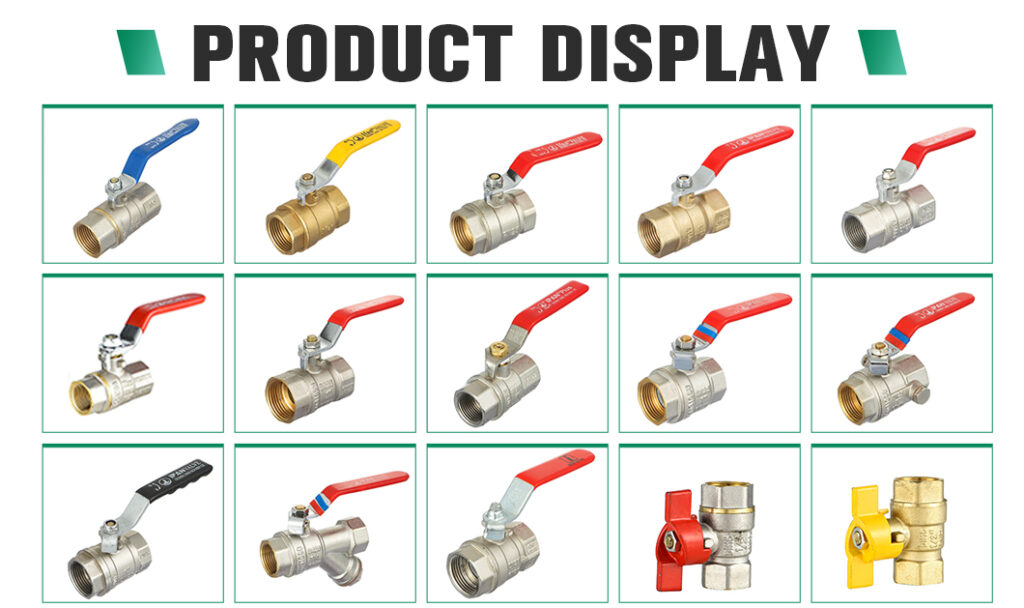

Correctly choose the type of valve

The correct choice of valve type is based on the designer’s full grasp of the entire production process and operating conditions. When choosing a valve type, the designer should first grasp the structural characteristics and performance of each valve.

Determine the end connection of the valve

Among thread connections, flanged connections, and weld end connections. Threaded valves are mainly valves with a nominal diameter below 50mm. If the diameter is too large, it will be very difficult to install and seal the connection. Flange-connected valves are more convenient to install and disassemble, but they are bulkier and more expensive than threaded-connected valves, so they are suitable for pipe connections of various diameters and pressures. Welded connections are suitable for heavier conditions and are more reliable than flanged connections. However, it’s difficult to disassemble and reinstall the valve connects by welding, so its use is limited to occasions that can usually operate reliably for a long time, or use severe conditions and high temperatures.

Selection of valve material

When selecting the material of the shell, internal parts, and sealing surface of the valve, in addition to considering the physical properties (temperature, pressure) and chemical properties (corrosiveness) of the working medium, the cleanliness of the medium (whether there are solid particles or not) should also be mastered. In addition, refer to the relevant regulations of the country and the user department. Correct and reasonable selection of valve material can obtain the most economical service life and best performance of the valve. The selection order of the valve body material is: cast iron-carbon steel-stainless steel and the selection order of the sealing ring material is: rubber-copper-alloy steel-F4.

Other

In addition, the flow rate and pressure level of the fluid flowing through the valve should determined, and the appropriate valve selection by using existing information (such as valve product catalogs, valve product samples, etc.)If you want to know more about our products, please feel free to contact IFAN, and we will provide you with the best choice!