Structure

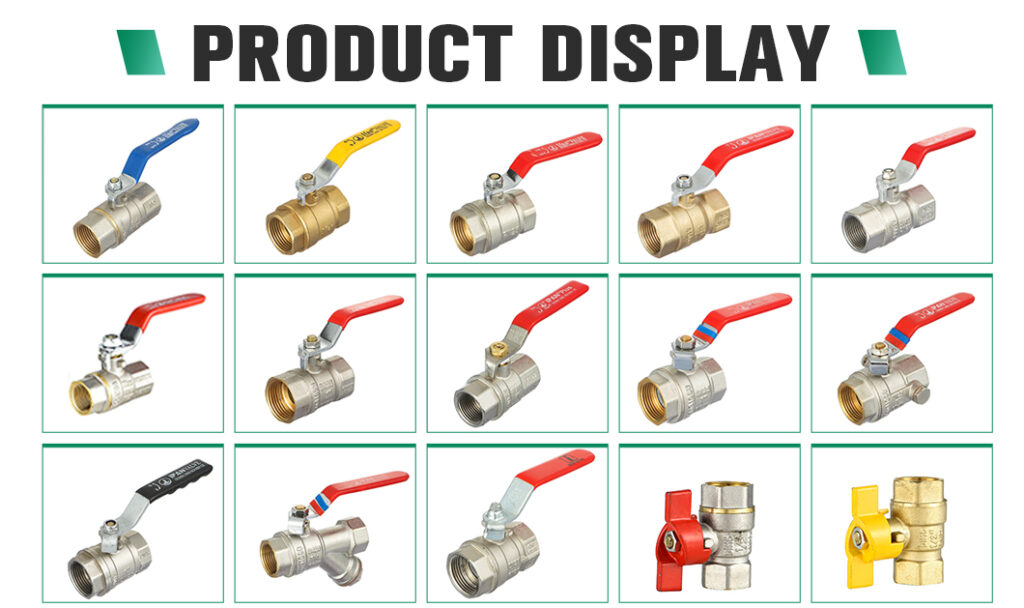

A brass ball valve is a type of valve that is commonly used in plumbing systems to control the flow of liquids or gases. It is made of brass, which is an alloy of copper and zinc. The brass ball valve consists of a spherical ball with a hole in the center, which is rotated by a lever or handle to control the flow of fluid through the valve. The ball is seated in a socket that is made of brass, stainless steel, or plastic. This is our Facebook Website:www.facebook.com,IFAN factory has 30+ years manufacture experience supporting color /size customization support Free Samples.

Material

The body of the brass ball valve is typically made of brass, which is a strong and durable material that is resistant to corrosion and wear. The ball itself is usually made of chrome-plated brass or stainless steel, which makes it resistant to rust and wear. The seals and gaskets in the valve are made of materials such as NBR, EPDM, or PTFE, which are all resistant to chemicals and heat.

Usage

Brass ball valves are versatile and can be used for a wide range of applications. They are commonly used in plumbing systems for controlling the flow of water, gas, and other fluids. They are also used in industrial settings, such as oil and gas pipelines, chemical plants, and refineries. Brass ball valves are popular because they are reliable, easy to use, and require minimal maintenance.

Installing a Brass Ball Valve

Installing a brass ball valve is a straightforward process that can be completed by a DIY enthusiast or a professional plumber. The following steps should be taken when installing a brass ball valve:

1.

Shut off the water supply: Before installing the valve, it is important to shut off the water supply to the area where the valve will be installed. This can be done by turning off the main water supply or shutting off the valve that controls the flow of water to the area.

2.

Prepare the pipe: The pipe where the valve will be installed should be cut to the appropriate length and deburred to remove any sharp edges or burrs. The pipe should also be cleaned and dried to ensure a secure connection.

3.

Attach the valve: The valve can be attached to the pipe using solder, compression fittings, or threaded fittings. The method used will depend on the type of valve and the type of pipe being used.

4.

Test the valve: Once the valve is installed, it should be tested to ensure that it is functioning properly. This can be done by turning on the water supply and checking for any leaks or irregularities in the flow of water.

Conclusion

In conclusion, the brass ball valve is a versatile and reliable valve that is used in a wide range of applications. It is made of brass, which is a strong and durable material that is resistant to corrosion and wear. The valve consists of a spherical ball with a hole in the center that is rotated by a lever or handle to control the flow of fluid through the valve. Brass ball valves are commonly used in plumbing systems for controlling the flow of water, gas, and other fluids, as well as in industrial settings such as oil and gas pipelines, chemical plants, and refineries. Installing a brass ball valve is a straightforward process that can be completed by a DIY enthusiast or a professional plumber.

If you want to know more about our products, please feel free to contact IFAN, and we will provide you with the best choice!