HDPE Pipe Price Considerations

Factors That Influence High-Density Polyethylene Piping Costs

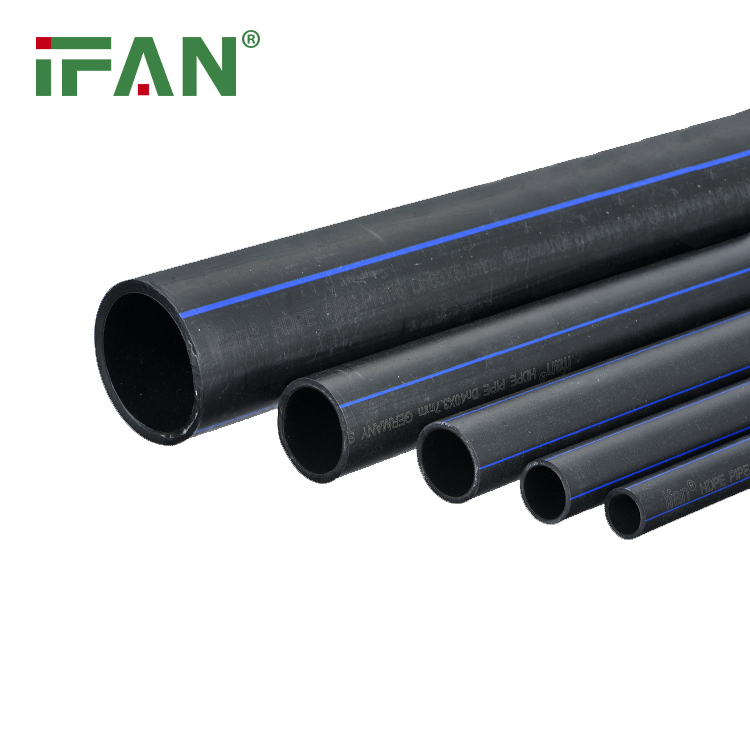

High-density polyethylene (HDPE) pipe provides an advantageous piping solution for municipal, industrial, agricultural, and other applications. But what determines HDPE pipe price and the key cost factors to consider? This article examines the influences on HDPE piping costs.IFAN factory with 30+ years of manufacturing experience supports color/size customization and free samples. Welcome to consult for catalog and free samples. This is our Facebook Website: www.facebook.com.

HDPE Material Supply and Demand

The cost of virgin HDPE resin directly affects finished HDPE pipe pricing. Resin is derived from ethylene, a product of natural gas and petroleum refining. Material costs fluctuate based on:

- Crude oil and natural gas prices impacting manufacturer margins

- Industry capacities and production economics

- Demand from HDPE producers and other sectors

When resin supply is tight or feedstock prices rise, HDPE pipe producers must pass along some cost increases. But HDPE material remains economical compared to steel.

HDPE Pipe Diameter and Dimension Ratio

The larger the diameter and thicker the wall of HDPE pipes, the more raw material is required, elevating the cost. Typical HDPE Dimension Ratios (DR) include:

- DR7 – Used for high-pressure transmission mains

- DR11 – Standard for municipal water distribution

- DR13.5 – Common for gravity sewer and drainage

- DR17 – Used in some low to moderate-pressure applications

Lower DR indicates thicker pipe walls and higher material volume and cost. But it allows higher pressures and burial depths.

HDPE Pipe Standard Specifications

HDPE pipe cost depends partly on the required strength class, tolerances, and testing standards:

- AWWA C901/C906 govern municipal HDPE water pipe specifications

- ASTM F714/F894 dictate requirements for municipal force sewer mains

- API 15LE establishes limits for hydrocarbon gathering and transmission piping

More stringent standards demand tighter quality control and production care, increasing costs. But they ensure suitability for critical service.

HDPE Pipe Manufacturing Process Factors

The production method for HDPE pipe impacts costs:

- Extrusion rate, number of heads – Faster cycles lower production cost

- Scrappage rate, material efficiency – Higher scrap means material waste

- Quality assurance steps – Extensive testing protects but adds cost

- Energy, labor expenses – Utility and wage costs affect margins

Optimized manufacturing maximizes quality while controlling expenses to allow competitive pricing.

HDPE Pipe Certification and Approvals

HDPE pipes must be certified to various codes and standards to verify their specifications. Compliance testing and documentation add cost but ensure fitness-for-use:

- Hydrostatic design validation per ISO and ASTM

- Stress regression validation of long-term strength

- NSF61 approval for potable water service

- Cell classification per ASTM D3350

Qualification by central standards agencies like NSF protects public health while meeting legal requirements.

HDPE Pipe Transportation and Logistics

Transporting bulky HDPE pipe reels/coils from manufacturing to project sites incurs fuel, labor, and equipment costs reflected in pricing. Key logistics factors include:

- Freight distance to delivery location

- Availability of flatbed trucks and trailers

- Pipe reel weight limits and sizes

- Accessibility of job site – impacts offloading complexity

Well-located production plants with optimized distribution channels help control logistics expenses.

HDPE Pipe Installation Factors

While not part of the material price, ease and speed of installation impact the total project cost. Pipe qualities influencing construction labor include:

- Length per reel/coil – Minimizes butt welds needed

- Flexibility – Eases snaking and reduces fitted joints

- Light weight – Lowers fusion equipment needs

- Durability – Prevents damage from handling and soil stresses

HDPE’s toughness enables simpler, faster installation than fragile PVC, ductile iron, or concrete. This saves labor which offsets material cost premiums.

Weighing Total Lifetime Value, Not Just Initial Price

HDPE pipe’s superior corrosion resistance, low maintenance, and reliable longevity deliver high value over decades of service. Its immunity to tuberculation and scale buildup maintains flow.

While the first cost plays a role, lifetime costs like replacement, downtime, and loss of service make HDPE piping highly competitive for essential pipelines.

IFAN

IFAN factory started in 1993. And IFAN has a workshop of 120000 square meters with 610 staff. IFAN can design and produce all plumbing pipe and fitting including PPR, PVC, CPVC PPSU HDPE PEXA PEXB PERT pipe and fitting, brass fitting, brass ball valve, heating system, gas system, sanitary faucets, and hose, In the past 30 years, IFAN has never forgotten his mission-To protect health and safety. And IFAN factory uses the best materials to produce high-quality pipe and fittings with an automatic production line and high-tech quality control machines.