Introduction

Exploring PPR Pipe Fittings: Types, Applications, and Industry Insights

Polypropylene Random Copolymer (PPR) pipe fittings are essential components in modern plumbing systems, offering a wide array of benefits. This comprehensive guide dives deep into the various types of PPR pipe fittings, their versatile applications across different industries, and provides valuable insights into the importance of these fittings in creating sustainable and efficient plumbing systems.IFAN factory 30+ years manufacture experience support color /size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website:www.facebook.com.

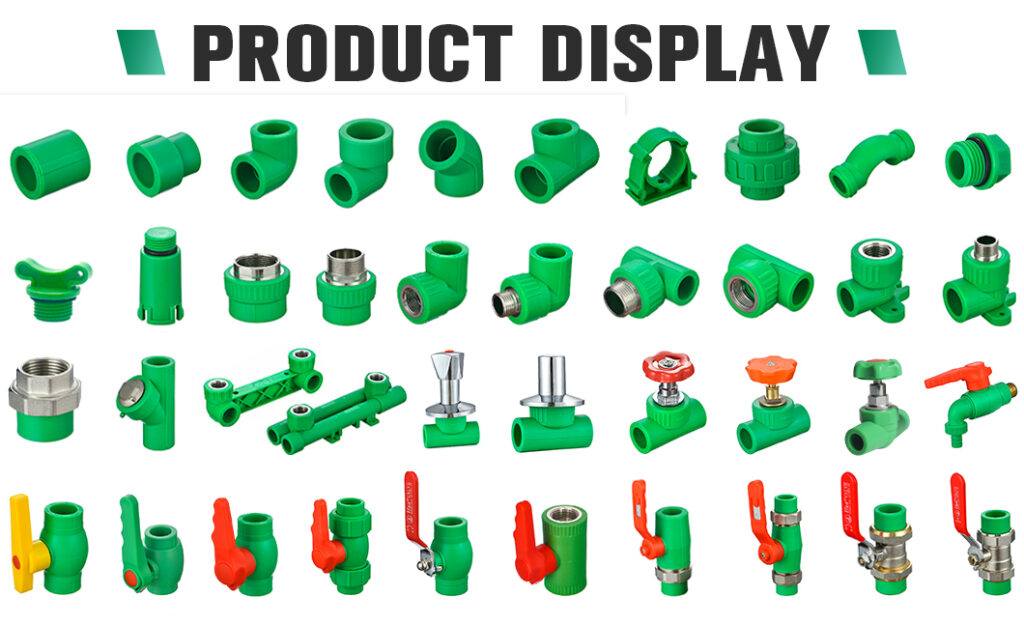

Types of PPR Pipe Fittings

1. PPR Couplings

PPR couplings are the cornerstone of PPR plumbing systems, serving as connectors to seamlessly join two PPR pipes. Available in various sizes, they ensure a reliable, leak-proof connection. These couplings are essential for residential, commercial, and industrial plumbing applications.

2. PPR Elbows

PPR elbows come in both 90-degree and 45-degree angles, allowing for smooth changes in pipe direction without the need for complex joints. They are commonly used in water supply and heating systems, offering flexibility in plumbing design.

3. PPR Tees

Featuring three outlets, PPR tees are vital for creating branch connections in plumbing systems. They find extensive use in potable water distribution, heating, and cooling systems, facilitating efficient fluid flow control.

4. PPR Reducers

PPR reducers are essential for transitioning between pipes of different diameters, ensuring a seamless flow of fluids. They are commonly employed in applications that require connecting pipes of varying sizes, maintaining uniformity in the plumbing system.

5. PPR End Caps

PPR end caps serve the critical role of sealing off the ends of PPR pipes, preventing debris and contaminants from entering the system, thereby maintaining water quality.

6. PPR Ball Valves

PPR ball valves offer precise control over fluid flow within plumbing systems. These valves are indispensable for shutting off water supplies or regulating flow rates, serving both residential and commercial needs.

7. PPR Pipe Clamps

Designed to secure PPR pipes to walls or other surfaces, PPR pipe clamps prevent pipe sagging. They are commonly found in heating and cooling systems, ensuring the stability of the pipes.

Applications of PPR Pipe Fittings

1. Residential Plumbing

PPR pipe fittings are widely used in residential plumbing systems for both hot and cold water distribution. Their corrosion resistance and long lifespan make them an excellent choice for delivering clean and safe drinking water to households.

2. Commercial Buildings

In commercial settings such as office buildings, hotels, and hospitals, PPR pipe fittings serve diverse applications, including potable water supply, HVAC systems, and fire suppression systems. Their durability and resistance to high water pressure are highly advantageous in these environments.

3. Industrial Facilities

PPR pipe fittings find applications in various industrial processes, including chemical processing, food and beverage production, and manufacturing. Their resistance to chemical corrosion and high-temperature tolerance make them suitable for transporting a wide range of fluids and chemicals.

4. Agriculture

PPR pipe fittings are essential components of agricultural irrigation systems, ensuring efficient water distribution to fields and crops. Their resistance to UV radiation and durability in harsh environmental conditions make them ideal for this purpose.

5. Renewable Energy Systems

PPR pipe fittings are integral to solar heating systems and geothermal heat pump installations. They facilitate the efficient transport of heated or chilled fluids, contributing to the sustainability of these energy sources.

6. Aquaculture

In aquaculture setups, PPR pipes and fittings play a vital role in providing a reliable means of water supply and drainage in fish farms and hatcheries.

7. Chemical Industries

PPR pipe fittings are essential for the chemical industry, ensuring the safe transport of various chemicals. Their resistance to corrosion and chemical reactions safeguard the integrity of the transport process.

Importance of PPR Pipe Fittings in Sustainable Plumbing

1. Reduced Leaks

PPR pipe fittings are renowned for their leak-resistant properties, reducing water wastage and the associated energy costs. This is instrumental in achieving water conservation and sustainability objectives.

2. Longevity

PPR pipes and fittings boast a long service life, minimizing the need for frequent replacements and the associated material and energy costs.

3. Energy Efficiency

The smooth interior surface of PPR pipes reduces friction and pressure loss, enhancing the energy efficiency of plumbing systems.

4. Chemical Resistance

PPR exhibits high resistance to corrosion, ensuring the structural integrity of pipes and fittings even in the presence of aggressive chemicals.

5. Recyclability

PPR is a recyclable material, and its fittings can be repurposed at the end of their life cycle, contributing to a circular economy.

Conclusion

PPR pipe fittings, with their diverse types and exceptional properties, play an indispensable role in various industries and applications, from residential plumbing to industrial processes. Their broad range of fittings and outstanding qualities make them an ideal choice for sustainable plumbing systems. By understanding the types of PPR fittings and their applications, we gain a profound appreciation for the significance of these components in modern infrastructure and their contribution to resource conservation and plumbing efficiency.