1. Introduction to Quality Control in ASTM F1974 Insulation Pipes

Quality control is crucial in ensuring that insulation pipes meet industry standards and performance requirements. Effective testing methods help identify defects and ensure Insulation Pipe reliability in applications.

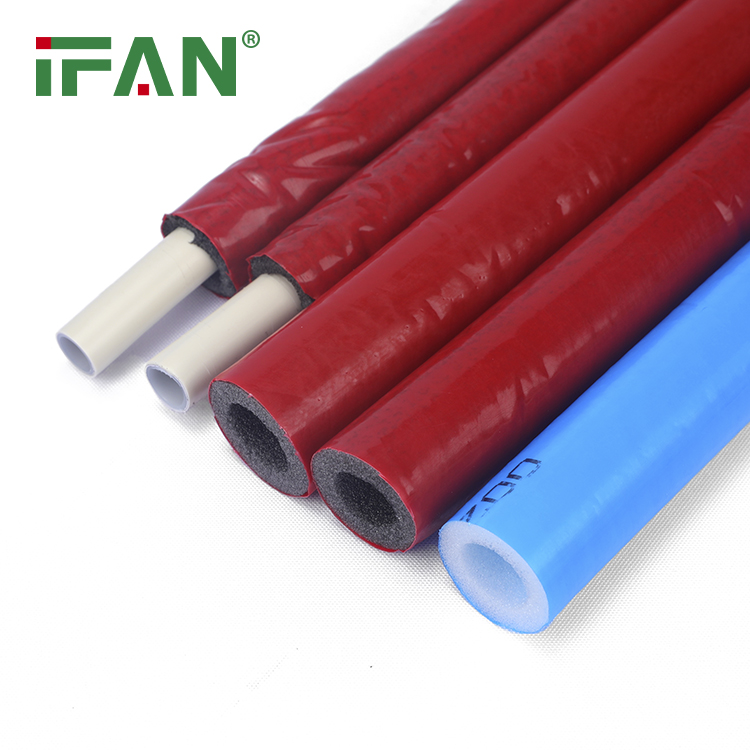

2. Visual Inspection

Visual inspection is the first step in quality control. This involves examining the exterior of insulation pipes for:

- Surface imperfections

- Proper installation of insulation materials

- Signs of damage or wear

3. Dimensional Verification

Accurate dimensions are critical for proper fitting and installation. Techniques include:

- Calipers and Micrometers: To measure diameter, length, and wall thickness.

- Laser Measurement: For high precision in larger pipes.

4. Thermal Performance Testing

Testing thermal insulation effectiveness is vital. Methods include:

- Heat Flow Meter Test: Measures heat transfer through the insulation.

- Guarded Hot Plate Test: Assesses thermal conductivity at controlled temperatures.

5. Pressure Testing

Pressure testing ensures the integrity of insulation pipes under operational conditions. Common methods include:

- Hydrostatic Testing: Involves filling the pipe with water and applying pressure to check for leaks.

- Pneumatic Testing: Uses air or gas to test the strength of the pipe.

6. Destructive Testing

Destructive testing methods help evaluate material properties and durability:

- Tensile Testing: Measures the strength and elasticity of the insulation material.

- Impact Testing: Assesses how materials behave under sudden forces.

7. Non-Destructive Testing (NDT)

NDT methods allow for thorough inspections without damaging the pipes:

- Ultrasonic Testing: Uses sound waves to detect internal flaws.

- Radiographic Testing: Employs X-rays to visualize the internal structure.

8. Environmental Testing

Insulation pipes must withstand various environmental conditions. Testing includes:

- Temperature Cycling: Simulates extreme temperature fluctuations.

- Moisture Resistance Testing: Assesses the impact of humidity on insulation performance.

9. Quality Assurance Documentation

Maintaining thorough documentation is essential for quality control. This includes:

- Test reports

- Compliance certificates

- Maintenance records

10. Conclusion

Implementing robust quality control methods for insulation pipe testing ensures durability, safety, and efficiency in applications. As technology advances, continuous improvement in testing techniques will further enhance quality assurance in the industry.

View more:https://www.ifanfittings.com/