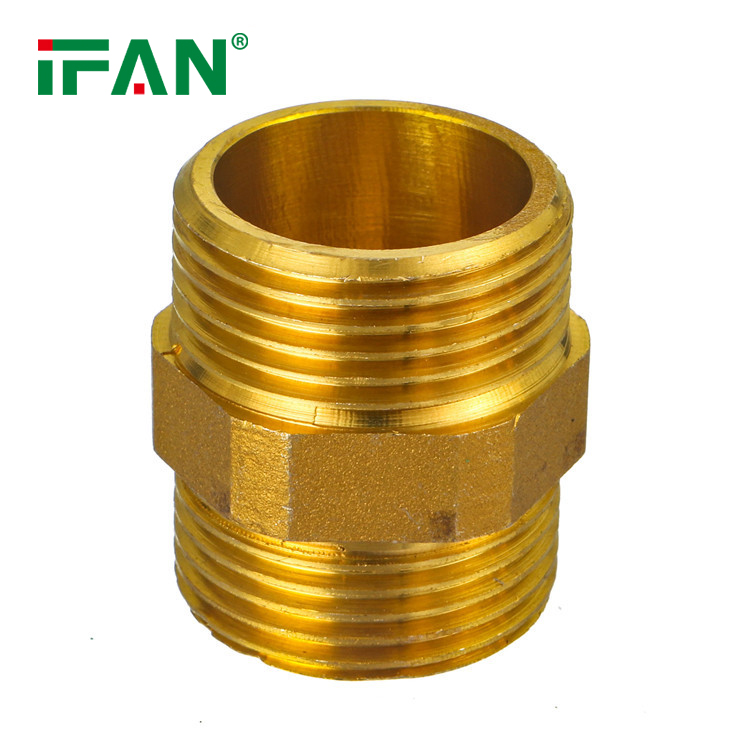

Before delving into their applications, let’s get a clear understanding of what Brass Connector Nipples are. These fittings are typically made from brass, an alloy of copper and zinc. Brass is chosen for its excellent corrosion resistance, making it an ideal material for components used in pipelines, where exposure to various fluids is common. The Brass Connector Nipple is designed with male threads on both ends, allowing it to connect two female-threaded pipes or fittings. IFAN factory 30+ years manufacture experience support color/size customization support free sample.Welcome to consult for catalog and free samples.This is our Facebook Website: www.facebook.com.

Diverse Applications of Brass Connector Nipples

Brass Connector Nipples find application in a wide range of pipeline systems due to their adaptability, durability, and corrosion resistance. Here are some key uses of Brass Connector Nipples:

1. Extending Pipeline Length

One of the primary functions is extending the length of a pipeline. By connecting two pipes, they effectively bridge gaps and create longer pipelines without compromising on the structural integrity.

2. Connecting Different Pipe Sizes

These fittings are invaluable when connecting pipes or fittings of different sizes. They ensure a secure, leak-free connection between pipes of varying diameters, enabling efficient fluid flow.

3. Pressure Regulation of Brass Connector Nipples

Controlling fluid flow and pressure is critical in pipeline systems. They are used to regulate pressure, redirect flow, and maintain the desired fluid dynamics.

4. Transition Between Materials

Pipeline systems often involve pipes made from various materials. They serve as connectors between these different materials, ensuring a secure and leak-resistant transition.

5. Custom Configurations

They are also used to create custom pipeline configurations. By combining them with other fittings and components, engineers can design complex pipeline systems that meet specific project requirements.

Advantages of Brass Connector Nipples

Opting for Brass Connector Nipples offers several advantages to the pipeline industry:

- Corrosion Resistance: Brass is well-known for its resistance to corrosion, making it suitable for a wide range of fluids, including water, gas, and oil.

- Durability: These fittings are exceptionally durable and can withstand the rigors of industrial environments.

- Leak-Free Seals: When properly installed, they provide tight, leak-free seals, ensuring the reliability of pipeline systems.

- Easy Installation: They are relatively easy to install, reducing labor costs and installation time.

- Versatility: They are versatile components that can adapt to various pipeline requirements.

Conclusion

In the complex and interconnected world of pipeline systems, they emerge as crucial components. Their corrosion resistance, durability, and adaptability make them a preferred choice for applications ranging from extending pipeline lengths to connecting pipes of different sizes. These versatile fittings play a pivotal role in maintaining the integrity of pipelines, optimizing fluid flow, and facilitating transitions between different materials. Brass Connector Nipples are undeniably vital contributors to the efficiency and reliability of pipeline systems, making them a cornerstone in the pipeline fittings industry.